Galling in Deep Drawing

Galling in Deep Drawing

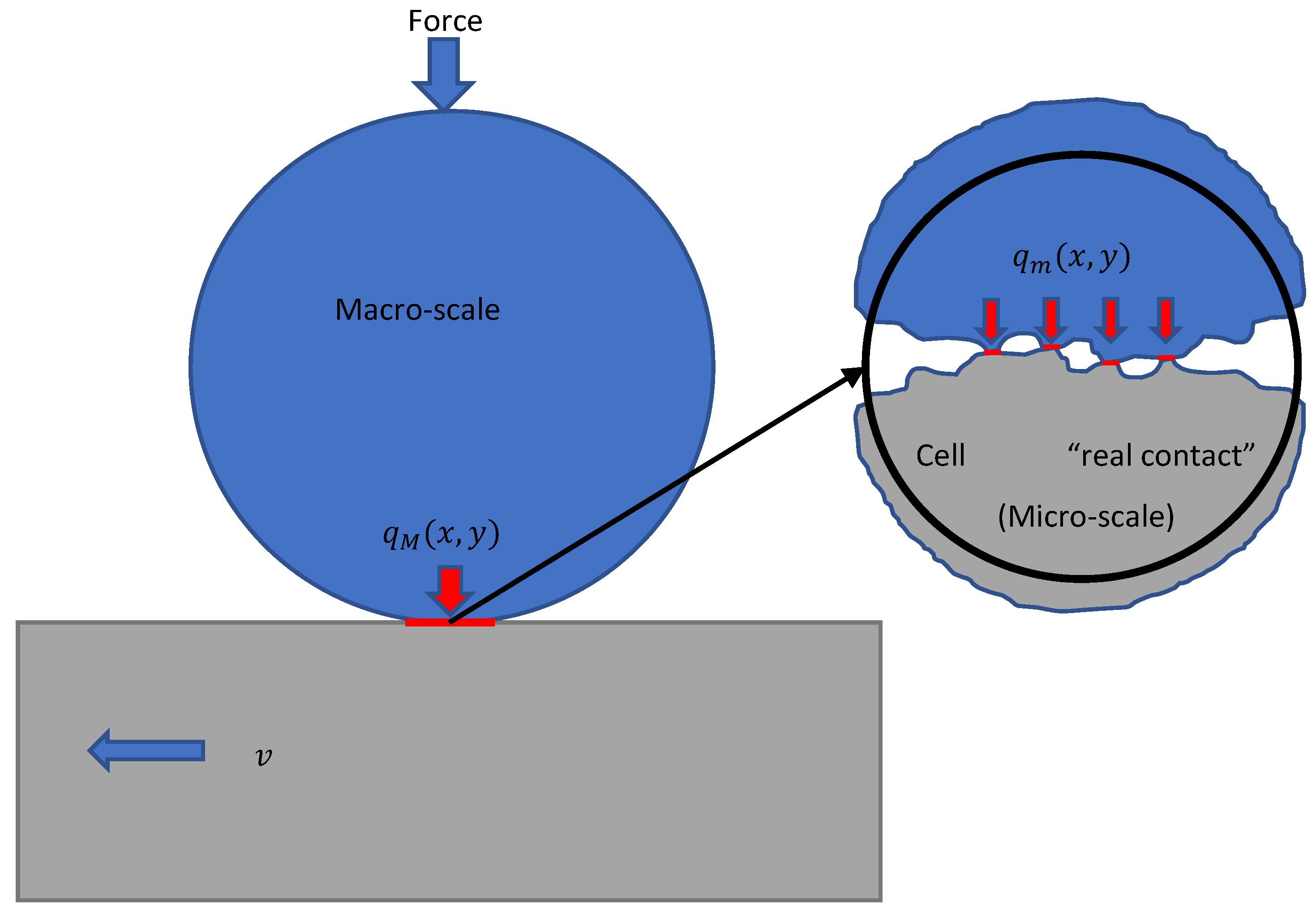

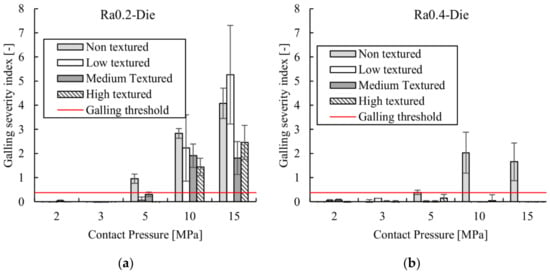

Contact in deep drawing can be divided into different scales, see figure 2. FEM simulations are typically concentrated on the macro scale, while galling plays a role on the smaller scales. On the meso scale, the relatively rough sheet is flattened when it is in contact with the smooth tool and plateaus are formed on the sheet. On the micro scale, the hard tool asperities plough through the flattened sheet plateaus. These ploughing asperities pick up material from the sheet metal. • Experiments are performed with a spherical shaped tip of tool material which scratches against a metal sheet, in order to simulate the micro scale behaviour. From these experiments the growth behaviour can be studied, see figure 3a.

The importance of the contact angle in deep drawing

Hydraulic Deep Drawing Press Machine

Analysis of the risk of galling in sheet metal stamping dies with drawbeads - Marcel Moghadam, Chris Valentin Nielsen, Niels Bay, 2020

Deep Drawing Process for Sheet Metal – IspatGuru

Tooling Archives - AHSS Guidelines

Deep Drawing Stainless Steel

Metals, Free Full-Text

Galling process during metal forming.

Deep Drawing - an overview

PDF] Predicting galling behaviour in deep drawing processes

Common defect in deep drawing process. a Wrinkling, b earing and c tearing

Analysis of the risk of galling in sheet metal stamping dies with drawbeads - Marcel Moghadam, Chris Valentin Nielsen, Niels Bay, 2020

Formability

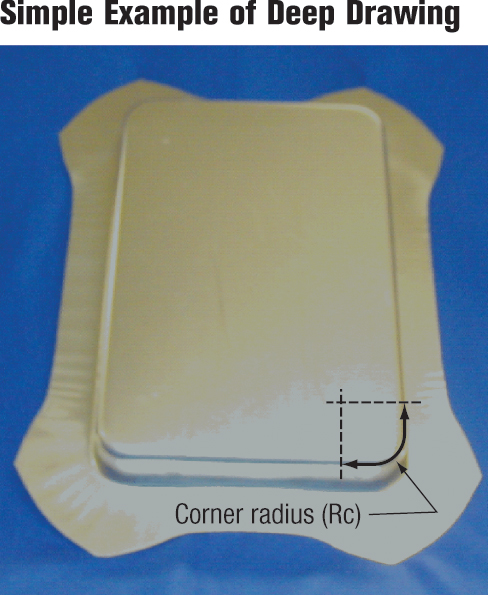

Deep Drawing from A to Z MetalForming Magazine Article